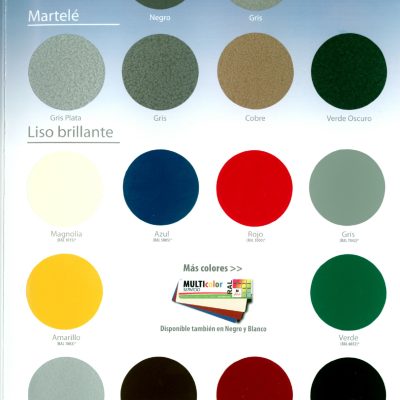

Polyurethane Enamel is a finishing product based on hydroxylated acrylic resins and aliphatic isocyanates. It is a highly resistant, smooth finishing product that stands out for its glossiness, chemical resistance and color retention.

Ideal for all metallic surfaces, aluminum and wooden surfaces. It is the perfect finish in anticorrosive systems if applied with the Epoxy Primer.

Application:

Mix in a ratio 5:1, preferably mechanically to achieve a homogenous result. Once the two components have been mixed together, there is an application time of 20 hours.

Apply on a clean surface, free of rust, dust and grease. Any remains of old paint must be removed. SA21/2 sandblasting is recommended.

Porous surfaces: Apply one coat of the Polyurethane Enamel as a sealer, diluted by 20% with PU solvent. Let it dry for 10 hours before applying the next coat.

Ferrous surfaces: For high anticorrosive resistance, apply two coats of Epoxy Primer with a minimum thickness of 50-60 microns. Let it dry for 24 hours and proceed with the application of the Polyurethane Enamel.

Light metals: The Polyurethane Enamel has a great adherence and compatibility with aluminum surfaces therefore there is no need for a primer. Clean the surface with an alkaline agent or any cleaner adding a small amount of ammonia and rinse with water.

Galvanized iron surfaces: Clean the surface with an alkaline agent or any cleaner adding a small amount of ammonia and rinse with water. Apply one coat of primer with a thickness of less than 10 microns. Let it dry for 24 hours and proceed with the application of the Polyurethane Enamel.

By brush: Rapid drying product, apply only small surfaces. Ready to apply or max dilution 5% with PU Solvent.

By roller/Spray Gun : Dilution level 5-10% with PU solvent.

Optimum results are obtained by spraying the product.

Drying time: 8 hours

Recoating time: 24 hours